a

Why ?

a

OUR COMMITMENT

a

OUR VISION

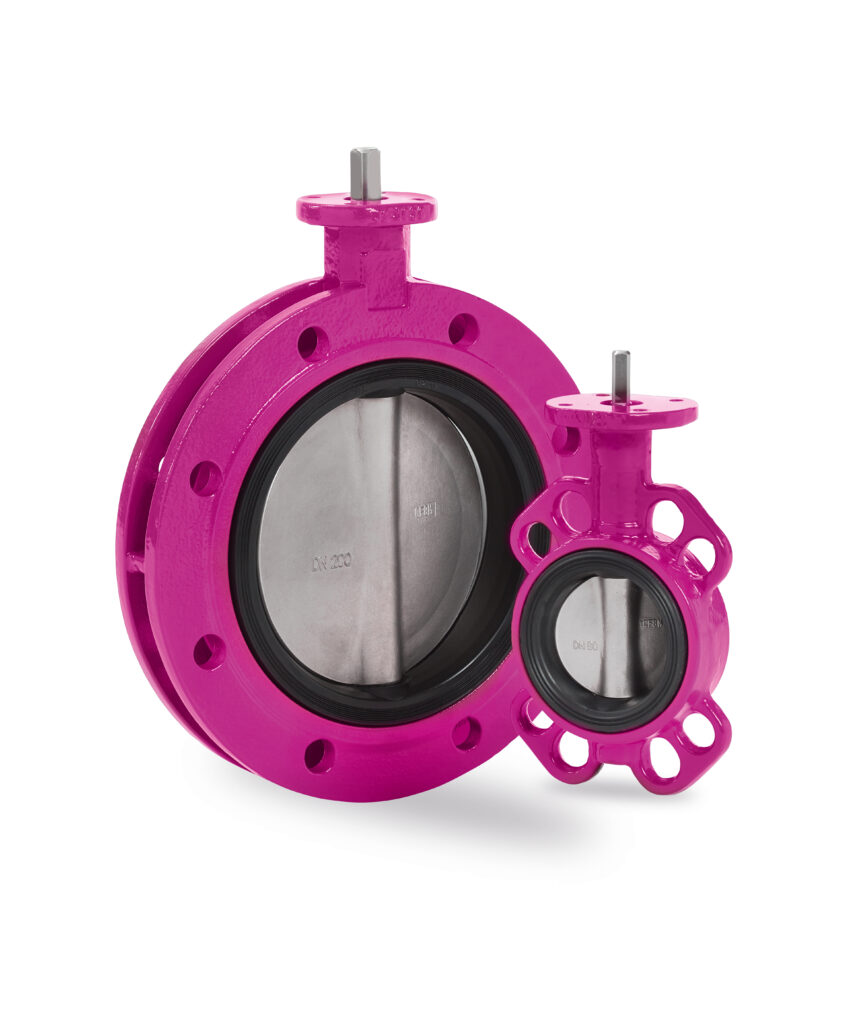

Standard Versions

Our range of products includes pipe components with PTFE/PFA lining according to DIN and ASME standards, manufactured with state-of-the-art welding and CNC machines. The lining is both paste-extruded and isostatic moulded in a manufacturing process that is unique in Europe. The result is a system that combines the mechanical strength of a metal housing with the corrosion resistance of a plastic liner.

These naturally comply with the Pressure Equipment Directive 2014/68/EU and have of course a ![]() - Certification.

Corrosion coatings up to C5 according to DIN EN ISO 12944 can be realised without any problems, in a variety of colours according to customer requirements.

Our product portfolio also includes PTFE/PFA-lined butterfly valves and ball valves (manually & externally actuated) as well as non-return valves and control valves in accordance with international standards and modularly configurable from numerous materials. Further components such as PTFE-Bellows, sampling devices with PTFE/PFA lining and PTFE hoses, as well as semi-finished products and coatings made of various fluoroplastics complete our product range. It goes without saying that almost all linings are approved for use in the food sector and therefore conform to FDA and EU standards. The entire production is subject to constant monitoring and is of course certified according to the DIN EN ISO 9001 quality management system. All production steps are documented so that complete traceability of individual components is always guaranteed.

- Certification.

Corrosion coatings up to C5 according to DIN EN ISO 12944 can be realised without any problems, in a variety of colours according to customer requirements.

Our product portfolio also includes PTFE/PFA-lined butterfly valves and ball valves (manually & externally actuated) as well as non-return valves and control valves in accordance with international standards and modularly configurable from numerous materials. Further components such as PTFE-Bellows, sampling devices with PTFE/PFA lining and PTFE hoses, as well as semi-finished products and coatings made of various fluoroplastics complete our product range. It goes without saying that almost all linings are approved for use in the food sector and therefore conform to FDA and EU standards. The entire production is subject to constant monitoring and is of course certified according to the DIN EN ISO 9001 quality management system. All production steps are documented so that complete traceability of individual components is always guaranteed.

Special Versions

PTFE-/PFA-coated or lined vessels, columns, collectors, injection- and dip pipes as well as strainers, sight glasses and ball check valves are just some of the options that can be manufactured to customer specifications. Expansion joints in special lengths or for only one type of movement, butterfly valves in special lengths or with reduced actuating forces, each individual requirement is checked regarding application and producibility. In close cooperation with the customer, we develop solutions that we implement specifically for the application. This very often involves space and room problems when changes and modifications in production processes are pending. The possibility of manufacturing components outside of given standards, always individually oriented to the customer's requirements, can almost always be realised on the production side. Here, too, the isostatic lining with PTFE is helpful in many cases, as it allows many geometric shapes that would hardly or not at all be solvable with paste extrusion.

Design & Construction

We provide assistance to the user from the very beginning in the planning, elaboration and finally the realisation of individual projects up to entire plants. In cooperation with the operator, often including an engineering consultant, we offer support in all matters from PTFE/PFA lined pipe components to butterfly valves and check valves as well as expansion joints and other components. Expert knowledge gained over several decades in the processing of fluoroplastics helps to identify possible solutions even for complicated requirements. Here, our focus is primarily on production processes that are as trouble-free as possible and a high degree of energy efficiency, which is a crucial aspect today more than ever.